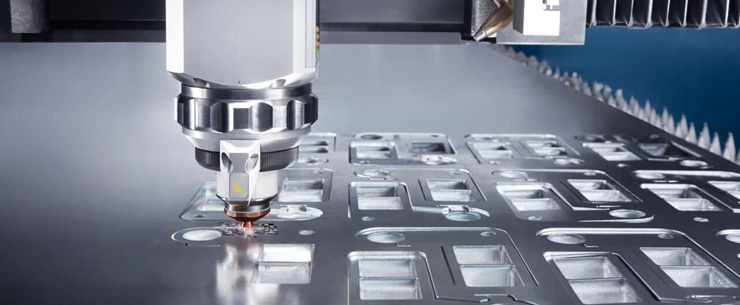

Advanced metal cutting technologies have revolutionized the manufacturing industry, allowing for the precise and efficient shaping of metals. These technologies offer improvements in speed, accuracy, material utilization, and the ability to cut complex geometries. They are essential in industries where high precision and quality are critical, such as aerospace, automotive, medical devices, and heavy machinery.

Benefits of Advanced Metal Cutting Technologies:

- Increased Precision and Accuracy : Advanced technologies provide highly accurate cuts, essential for applications requiring tight tolerances and complex geometries.

- Enhanced Material Utilization : These technologies minimize material waste by precisely cutting only the necessary portions, making them more cost-effective.

- Faster Production Times : High-speed processes and reduced setup times lead to faster production cycles, increasing overall productivity.

- Improved Surface Finish : Advanced cutting methods produce smoother surfaces, reducing or eliminating the need for additional finishing processes.

- Versatility : These technologies can cut a wide variety of materials, including metals, composites, and ceramics, making them adaptable to different industries and applications.

- Aerospace : Precision cutting of components like turbine blades, structural parts, and complex assemblies.

- Automotive : Cutting engine components, body panels, and custom parts with high precision.

- Medical Devices : Manufacturing surgical instruments, implants, and diagnostic equipment that require intricate designs and biocompatibility.

- Defense : Cutting of armor, weaponry, and military vehicle components with high accuracy and durability.

- Electronics : Precision cutting of housings, connectors, and other small, detailed components.